When You Short Yourself

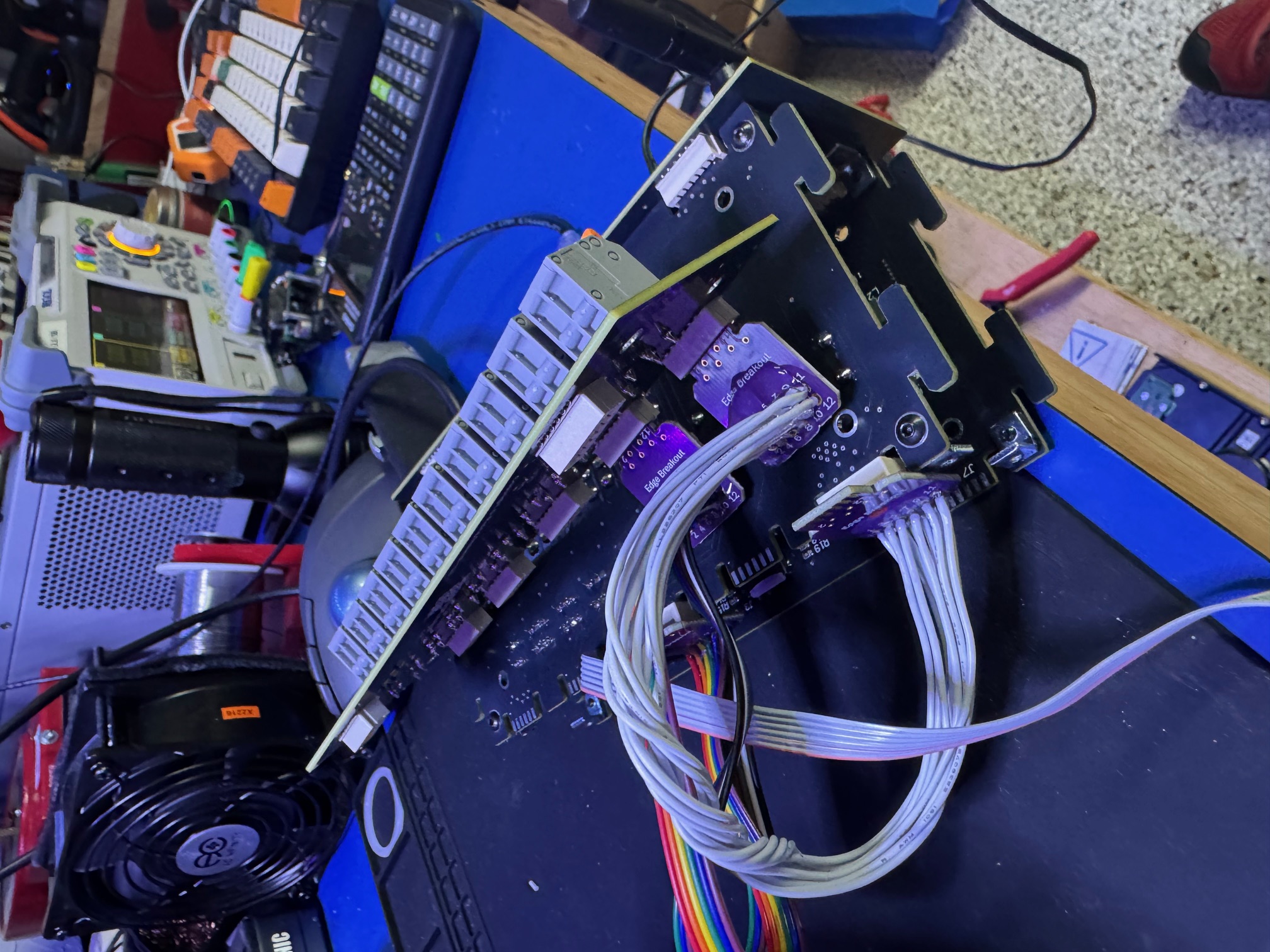

I was working on testing a new design and because the pinout was different than the previous design, I had to make a few cables for jumping the connectors between boards. Basically they were simple little PCB edge connectors connected via ribbon cable for data lines and real wire for power buses. This way I could easily connect the correct signals to the correct pins on the board under test. I thought I'd be clever and just sit the test board on top of the other board while testing.

The Setup

The Problem

The problem was that I didn't think about the fact that my little cables were not covered and I could easily touch the power rail (12VDC) to a data rail if I wasn't careful. Well guess what happend... I shorted the power rail to a data rail.

So now I had a problem... This was a new board and I didn't have any spares. I had to fix it. Luckly it didn't brick the main board or the onboard microcontroller. It seemed like only two things had taken the hit.

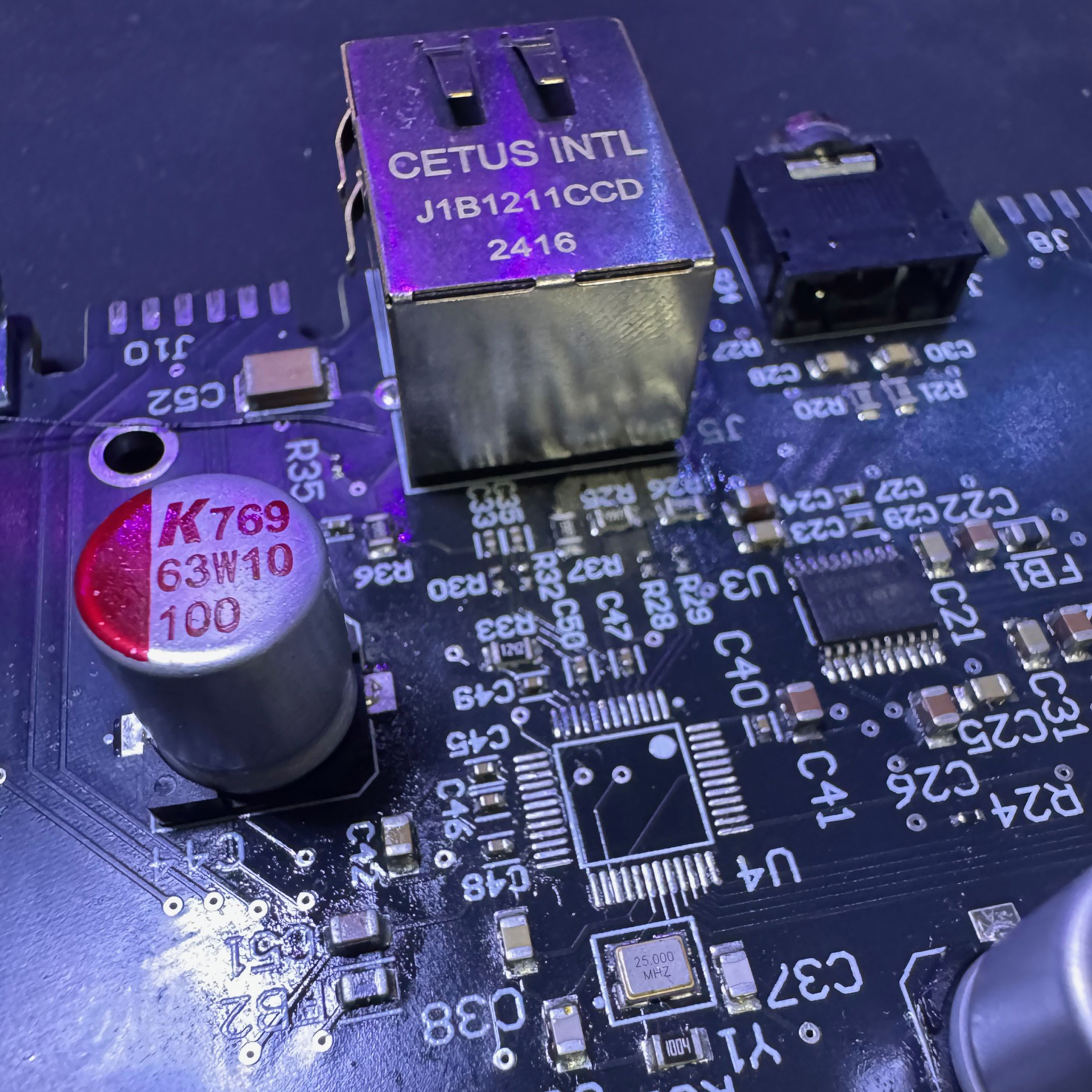

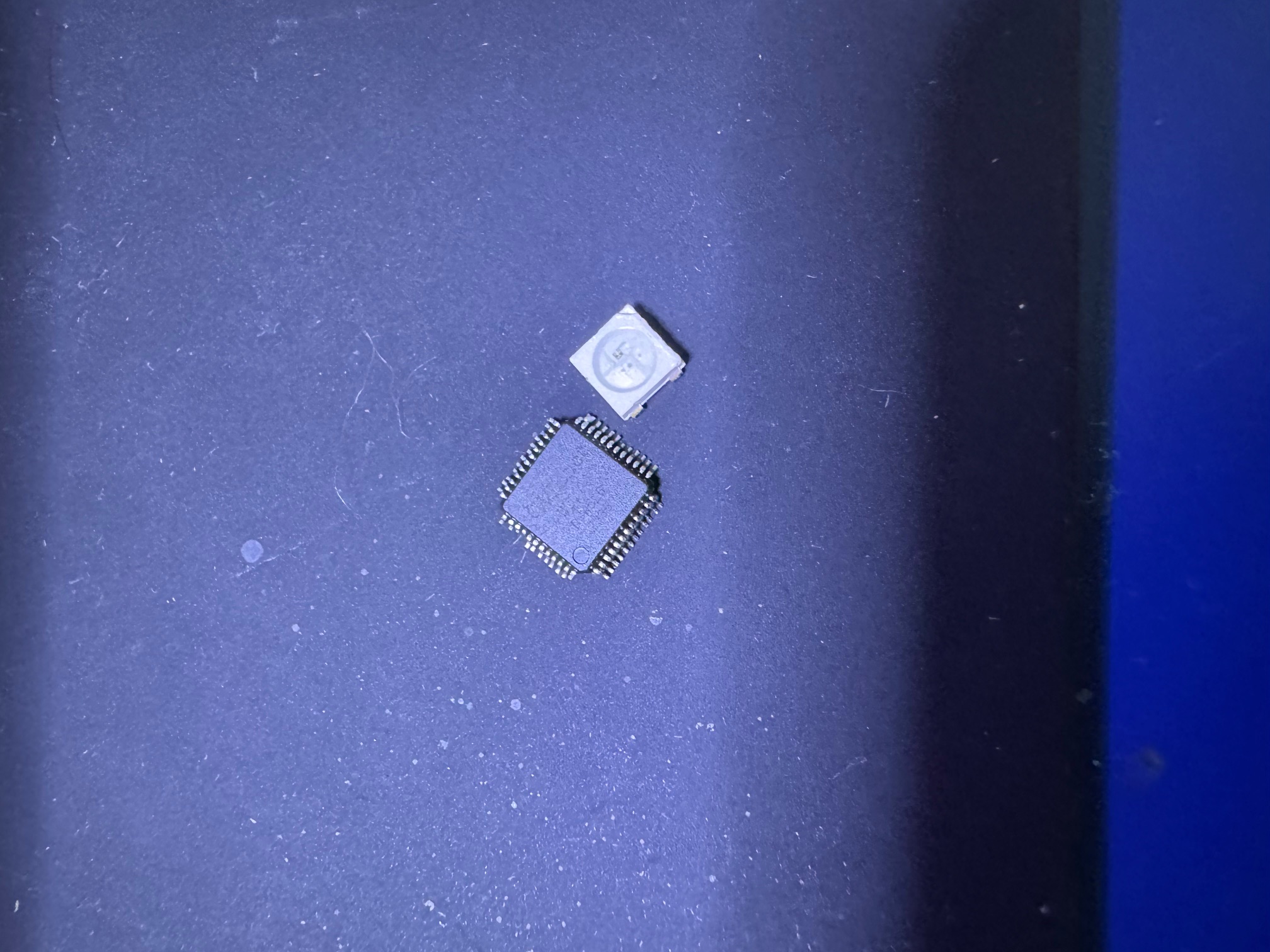

The first was the Ethernet PHY chip which you can see here wasn't even powering on anymore. The second problem was that one of the addressable LEDs also took a hit and stopped lighting up and sending data down the line.

![]()

Great... I had to fix this. I didn't have any spares and I needed this board for testing and continued firmware development. I have a deadline looming and I can't wait for a new board to arrive.

The Fix

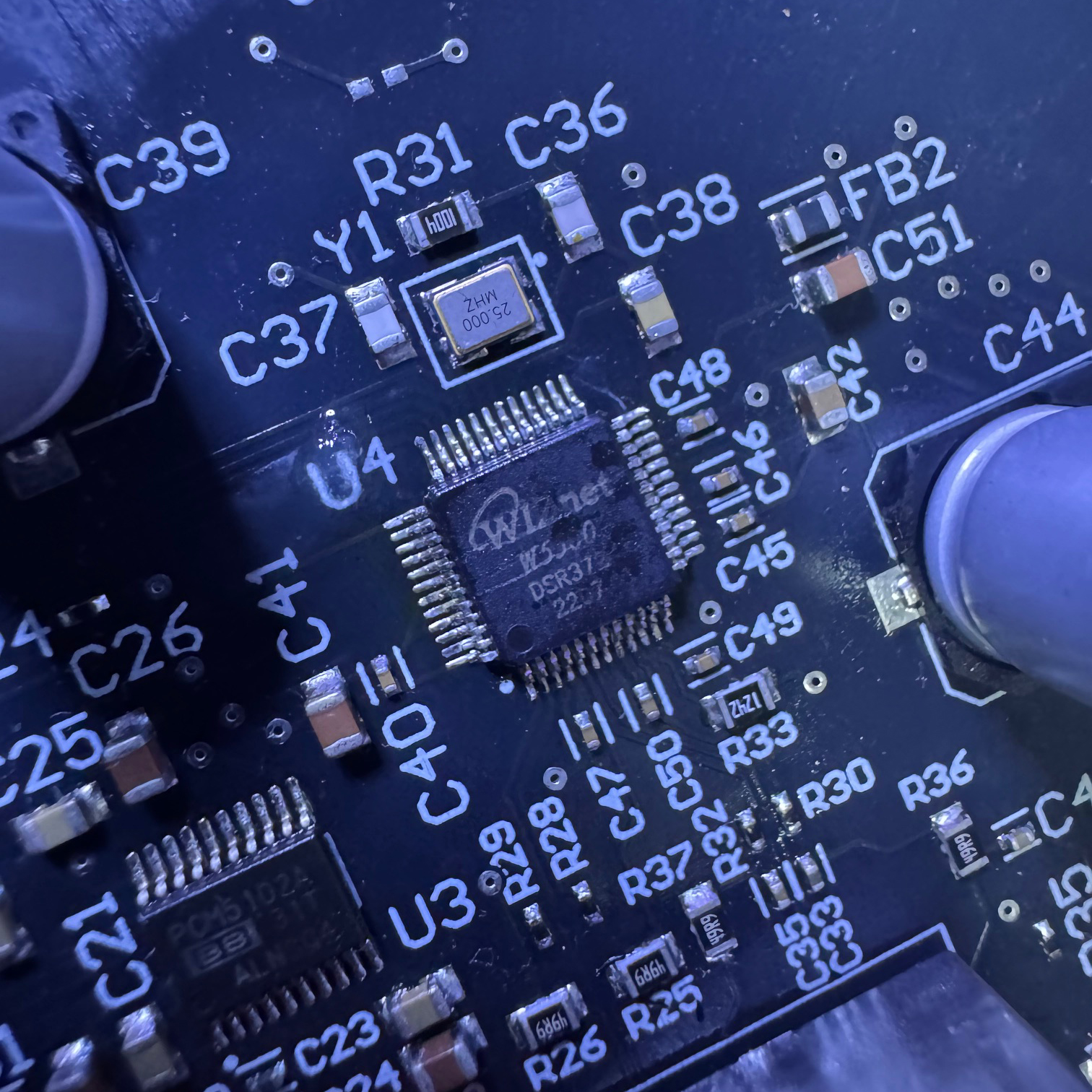

The first thing was to address the dead ethernet chip. I had to remove it and replace it. I had a few spares of this chip so it wasn't a big deal from that point of view. The problem is that this is a W5500 and has a 48 pin QFN package which is a pain to align when there isn't any solder on the pads. So the first thing I did was fire up the hot air rework station and remove the dead chip.

Now that I have the chip off.. I have to clean up the pads get ready for the new chip. This is a pain because the pads are so small and aligning the new chip is a pain. I had to use a microscope to make sure I was getting the chip aligned correctly and, of course it didn't the first.... 4 attempts! I ended up destroying a new one in the process of trying to force the alignment (don't do that). I finally got it aligned and soldered down.

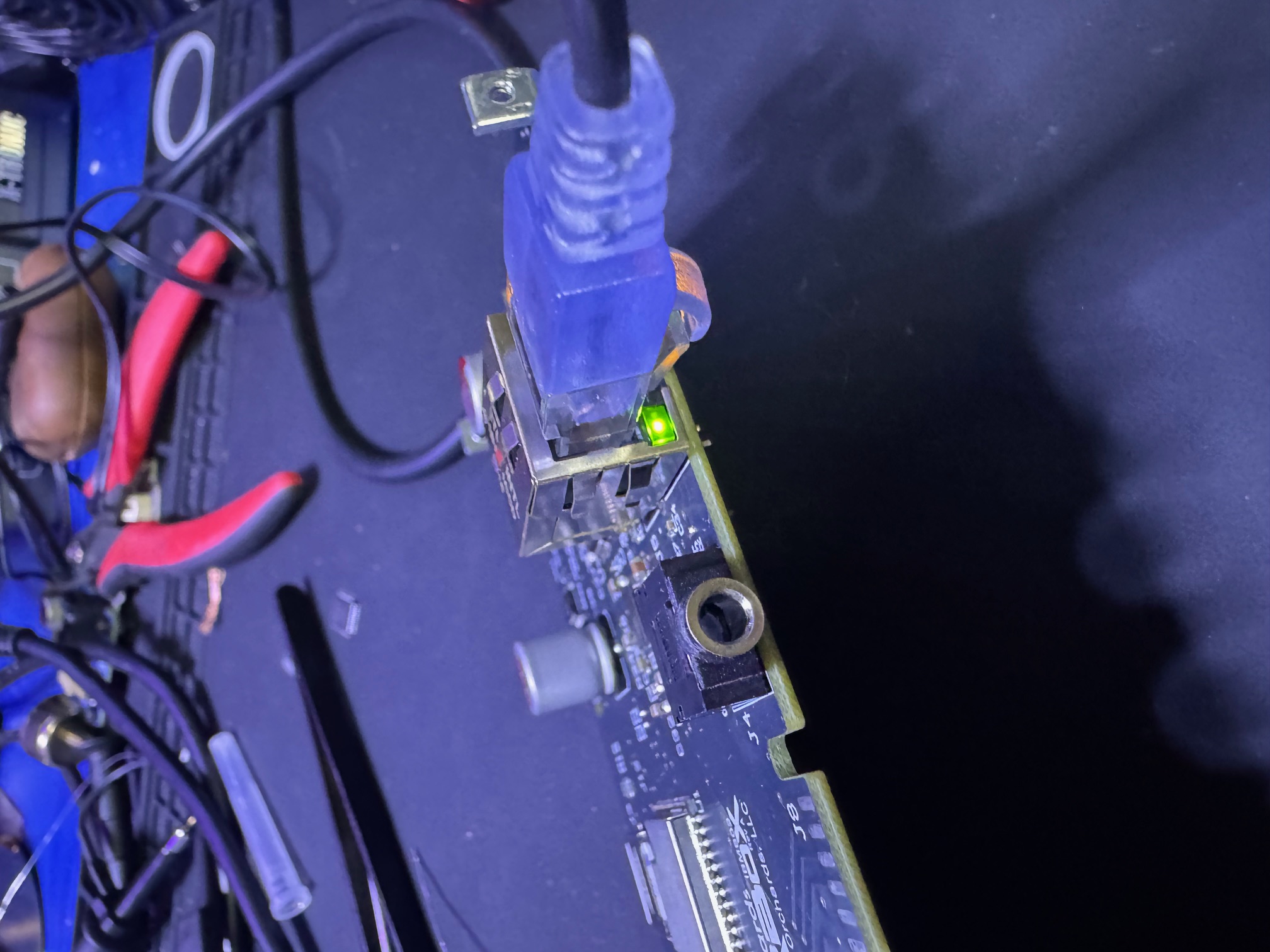

If you look really closely you can see that the chip is a little off center, but not enough for any pins to short to adjacent pads. Plus after a literal hour of muttering obscenities under my breath and 2 dead chips later, I was not going to try again. I powered up the board and the Ethernet port lit up! Success!

After this I had to address the dead LED. This was a little easier because I had a few spares of these as well. I had to remove the dead LED and replace it. After doing a 48 pin QFN package, this was a walk in the park. I removed the dead LED and replaced it with a new one. I powered up the board and the LED lit up! Success again!

The Lesson

The lesson here is to always cover your cables when testing or at least be mindful of what voltages are where. I should have put some heat shrink tubing over the connector solder points to prevent this from happening. I was lucky that I didn't brick the board and that I had spares of the parts that took the hit. I could have easily been in a situation where I had to wait for a new board to arrive and that would have pushed my deadline back. I learned my lesson... probably. I hope you learn from my mistake and do the same.

The casualties of my mistake:

(the other W5500 is no where to be found as I threw it across the room in frustration)

If you'd like to submit your own Engineering Hell stories, we'd love to publish them: Share your Story